Product

What is "Site-Built Modular"?

Understanding Type Five's design-build approach

At Type Five, we’ve developed a novel homebuilding system we call “site-built modular.” This method bridges the gap between the expensive, traditional architect-led processes and the restrictive nature of prefab construction, offering a middle ground that promises both customization and affordability.

Amidst a nationwide housing crisis, homebuilding remains too slow and expensive in the United States. Excluding high-end single-family residences, the average quality of new housing built in the US is also relatively low. As a software-enabled architecture firm and a general contractor, Type Five is developing technology that allows us to design, permit, and build better, faster, and cheaper.

Today, two dominant delivery methods exist for residential construction. The first, a traditional architect-led design/bid/build process, amounts to reinventing the wheel with each new project and is cost-prohibitive to most potential homeowners. The second, a volumetric or panelized prefabricated approach, offers efficiencies and economies of scale. However, this method is highly constrained regarding how much clients can customize the home to their specific needs and site conditions.

Using modular design to standardize site construction

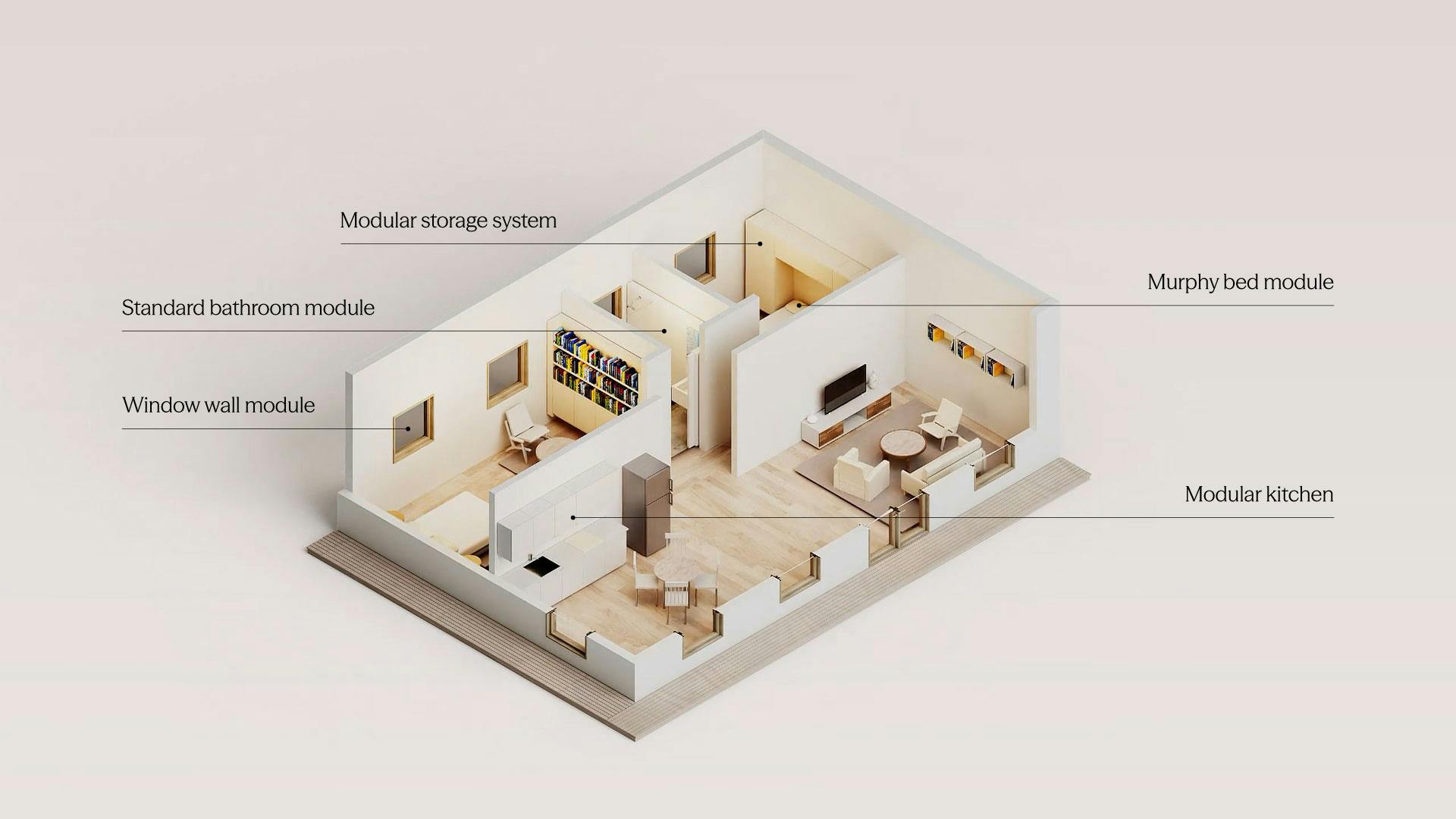

Modular construction is born from the fact that modern buildings are groupings of repetitive, distinct parts and components, and therefore, designing and building with this in mind can be done highly efficiently and consistently. The size of the modules themselves may vary widely within this technique: the module may be as small as a structurally insulated wall panel or as large as an entire residential unit. Typical prefabricated modular construction manufacturers standardized building components in an off-site factory to an extremely high degree of precision and engineered to be transported on a highway and possibly up into the air by crane.

Type Five is dissociating modular construction from prefab construction. We have developed a design system that utilizes modular construction principles alongside the time-tested, contingency-proof realities of in-situ construction.

If we let go of the idea that we will build homes in a factory, what is left to gain by thinking about building with modules? It turns out quite a bit. By standardizing and integrating building elements like Murphy beds, kitchens, bathrooms, casework, etc., into our toolkit, we have massively expedited the design process, our permitting procedures, and the on-site construction itself. This is what we are calling “site-built modular.”

Tech-enabled design efficiency

Our core technology uses advancements in Building Information Modeling (BIM) coupled with programming via Grasshopper and ShapeDiver to allow consumers to design homes on our website. From there, we can instantaneously generate consistent, error-free construction documents directly into permitting and construction. This technology has not only helped us expand and refine our design system, but it also immediately allows customers to understand its versatility and quickly develop a sense of authorship over the design of their homes. This has been essential in reducing the number of design meetings, revisions, and studies required to arrive at a final layout and submit it for a building permit.

Architecture and software could be considered inextricably entangled; for example, in 2007, Frank Gehry’s office needed to develop an entirely new software called Digital Project to execute geometrically complex projects such as the Guggenheim Bilbao and the Walt Disney Concert Hall. Instead of platforms that can optimize and discretize complex sculptural surfaces, we’d like to see a new suite of applications explicitly geared toward optimizing residential construction. How can we build housing faster and better? That is the question we hope to answer with our software.

Our ability to rapidly iterate on our design system means that we can constantly improve our construction methods across similar projects.

Democratizing residential architecture

If architect-led design/build is bespoke tailoring and production builders are off-the-rack clothing, Type Five offers a made-to-measure solution to create custom-designed homes at affordable prices using a systematic design approach.

Our customers arrive at our website and input their address, which allows us to pull specific information about jurisdiction and lot features. Customers then begin by inputting the size of the home they are hoping to build. Our configurator currently supports studios, one-bedrooms, and two-bedrooms, although our system can accommodate much larger arrangements.

The next step is to select their preferred building typology; we offer standard linear, L-shaped, double-wide, and two-story plans. Specific site requirements or aesthetic preferences may inform these choices. Within each of these types, we offer several preset layouts from which the customer can choose. The user can then customize features like exterior material, color, window sizes, door locations, etc., which are all reflected in a live cost calculator. Once the client is satisfied with their design choices, they submit this information to us, and we can initiate the project, set a schedule, and prepare for permitting.

After the client has finalized the major decisions about their home, such as the overall dimensions, the number of bedrooms and bathrooms, and the location of plumbing fixtures, we move on to a secondary design choices portal where the clients can select interior finishes, hardware, and appliance upgrades. Our clients are often drawn to us for the quality of our work and the versatility of our designs, and we quickly find that we are competitive on pricing and schedule as well.

Before Type Five, our team spent several years in boutique architecture firms working on luxury residential projects. We would meticulously pore over every bespoke detail of the home, going back and forth with clients several times until arriving at a decision. Type Five aspires to provide the customization and service that a design-focused architecture firm offers at a lower cost and a more immediate turnaround between design decisions and outputs.

Most homes we are building are Accessory Dwelling Units (ADUs) in the San Francisco Bay Area, which are between 300 and 1000 sqft. ADUs have been productive testing grounds for us for several reasons. The first is legislation California has been introducing to ameliorate the state-wide housing crisis, making acquiring building permits for accessory dwellings easier and faster. The second is the vast variety of use cases our customers have in mind for their ADU, from an art studio to a home office to a rental unit to a part-time apartment for extended family; ADUs are NOT one-size-fits-all. The versatility of our system allows us to build for these specific scenarios in a way that traditional prefab cannot.

We’ve built a tight feedback loop with our network of subcontractors. Our ability to rapidly iterate on our design system means that we can constantly improve our construction methods across similar projects. This reduces waste on the job site and allows us to standardize the use of high-quality and sustainable materials throughout our projects.

As we move beyond accessory dwelling units into larger single-family homes and multi-family projects and into new geographic markets and jurisdictions, the number of scenarios we need to accommodate within our system increases exponentially. Fortunately, we see this as an exciting challenge.

Ian Miley

Head of Design